Digital Twin

Digital Twin

Are you looking to take your business to new heights of success and efficiency? Introducing our revolutionary Digital Twin solution, the game-changer that will transform the way you operate and optimize your assets.

What is a Digital Twin?

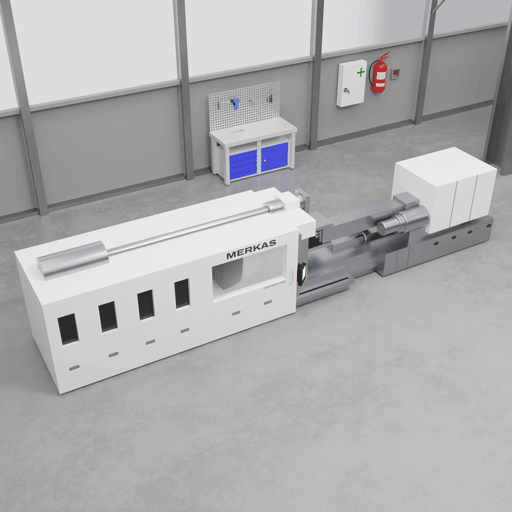

What is a Digital Twin, you ask? It's a virtual replica of your physical assets, a digital counterpart that mirrors their real-time behavior, characteristics, and performance. With our state-of-the-art technology, you can now have an accurate and dynamic digital representation of your machinery, equipment, or infrastructure.

Benefits

Using 3D digital twin applications for machinery offers numerous benefits that can significantly enhance operations, productivity, and decision-making. Here are some key advantages:

Visualize and Simulate

3D digital twin applications provide a realistic visual representation of machinery, allowing users to visualize complex components, assemblies, and systems. With accurate simulations, you can test different scenarios, analyze performance, and optimize operations without the need for physical prototypes or real-world experimentation.

Collaboration and Communication

Digital twin applications promote collaboration and communication across teams and departments. Different stakeholders, such as engineers, operators, and managers, can access and interact with the digital twin, share information, and collaborate on projects or problem-solving. This enhances transparency, coordination, and knowledge exchange within the organization.

Virtual Training and Education

Digital twins enable immersive training experiences for operators, technicians, and maintenance personnel. Through interactive tutorials and virtual environments, employees can learn how to operate, service, and troubleshoot machinery effectively. This reduces training time, minimizes human errors, and ensures a skilled workforce.

Cost and Time Savings

By utilizing digital twins, businesses can save costs and time in various ways. Virtual simulations allow for faster prototyping and testing, reducing the need for physical iterations.

Core Features

3D model import

Bring your machinery to life with our digital twin solution's ability to import and animate 3D models. Showcase intricate details, demonstrate functionality, and simulate real-world scenarios with realistic animations. This feature adds depth and realism to your virtual environment, enhancing the understanding and engagement of users.

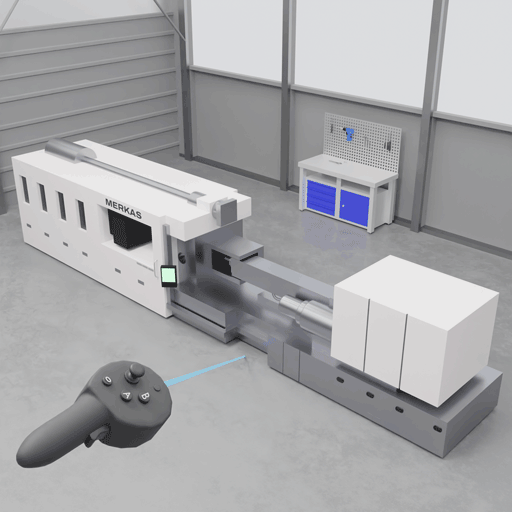

Custom Navigation

With our digital twin solution, you have the freedom to design navigation controls that suit your requirements. Whether it's a joystick, touchpad, or gesture-based controls, you can create an intuitive and immersive navigation experience that enables users to explore and interact seamlessly with the virtual environment.

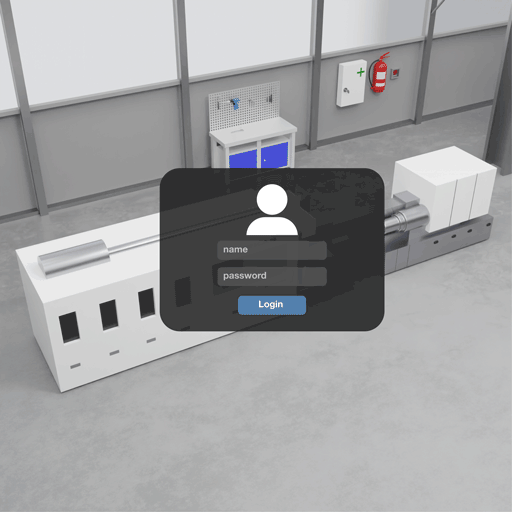

User Management

Maintain control and streamline access with custom user management. Define user roles, permissions, and access levels to ensure that the right people have the right level of access and functionality within the system. Efficiently manage users, track progress, and customize experiences based on individual roles and responsibilities.

Customizing options

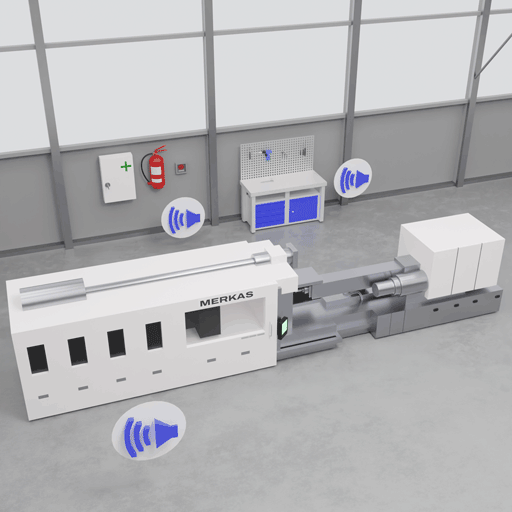

Audio

Immerse users in a rich and realistic environment with custom audio integration. Whether it's ambient sounds, machinery noise, or interactive audio cues, our digital twin solution allows you to incorporate custom audio elements that enhance the overall experience, making it more engaging and true to life.

Custom branding

Tailor the app to your brand, allowing you to create a fully immersive experience that reflects your unique identity. Leave a lasting impression on your audience.

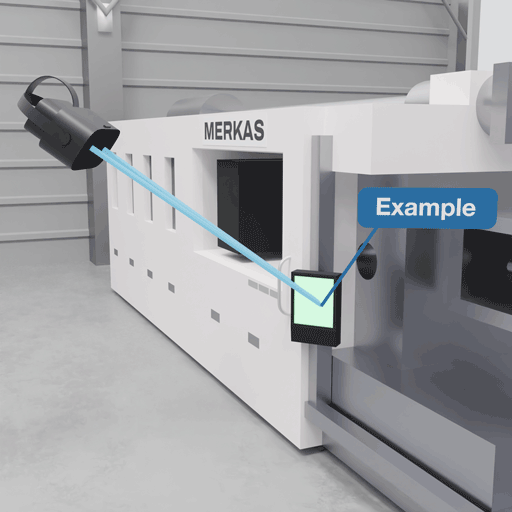

Custom Eyetracking

Experience the benefits of eyetracking technology, enabling hands-free interaction with your digital twin. By tracking eye movements, users can effortlessly control and navigate the virtual environment, providing a truly immersive and intuitive experience.

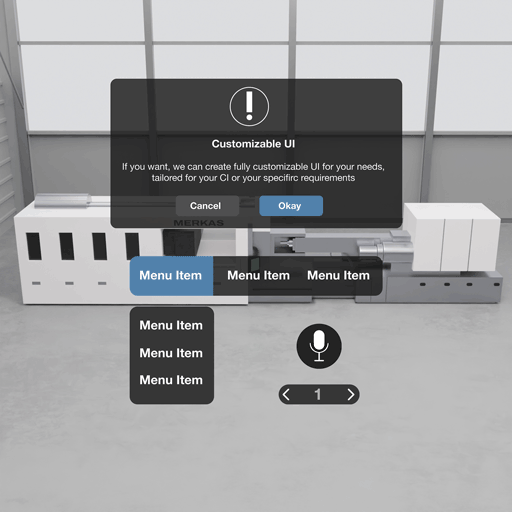

3D World UI

Elevate user interactions with a custom 3D world user interface (UI). Create interactive menus, information displays, and control panels that seamlessly blend into the virtual environment. This intuitive UI enhances usability, simplifies navigation, and ensures a cohesive and immersive user experience.

Advanced controls

Seamlessly navigate through the digital twin with intuitive controls that put you in complete command. Experience full fluidity of movement tailored to match your requirements.

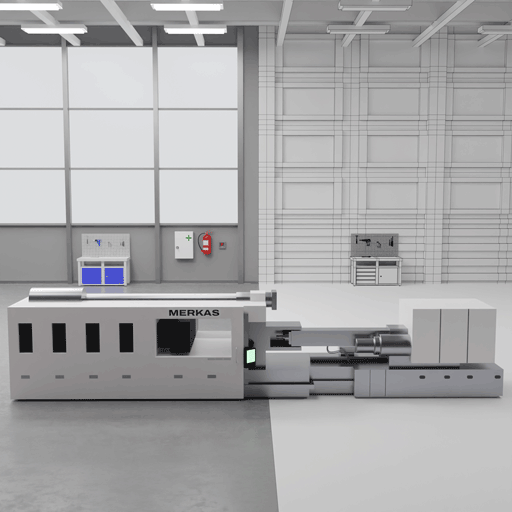

Environment design

Create unique and immersive virtual environments tailored specifically to your needs. Whether it's a factory floor, an industrial site, or a customized training environment, or even your own facility - our digital twin solution allows to replicate your real-world settings, enabling realistic training, visualization, and interaction.

Gesture recognition

Take control of your digital twin using custom gesture recognition. With advanced gesture tracking technology, users can interact with machinery, manipulate objects, and trigger actions simply by using hand gestures. This intuitive and natural interface enhances user engagement and efficiency.

Platform independent

Our digital twin solution is platform-independent, meaning you can deploy and access it across various devices and operating systems. Whether it's desktop, mobile, or virtual reality (VR) headsets, you can enjoy the flexibility of using the solution on the platform of your choice, ensuring seamless access and utilization for your entire team.

Contact us today to schedule a personalized demonstration and discover how our Digital Twin solution can propel your business forward.

Engaging and Immersive Experiences

Step into a virtual world where machinery comes to life. Our framework creates highly realistic and interactive environments that replicate real-world scenarios, allowing users to learn in a hands-on and engaging manner.

Ongoing Support and Updates

We're committed to your success. Our support is always ready to assist you throughout the implementation and adoption process. We continually enhance our framework with new features and updates to ensure you stay at the forefront of VR-based machinery learning.

Real-Time Performance Tracking

Monitor your progress and identify areas for improvement through our integrated analytics dashboard. Gain valuable insights into their performance, knowledge retention, and skill development. Make data-driven decisions to optimize training programs and maximize ROI.

Cost-Effective Solution

Investing in VR technology can be a significant financial commitment. However, our solution offers a cost-effective approach by leveraging existing VR hardware or providing affordable alternatives. Experience the benefits of VR without breaking the bank.

FAQ

A digital twin is a virtual replica or representation of a physical asset, system, or process. It utilizes data from sensors, simulations, and other sources to mimic the behavior, characteristics, and performance of the physical counterpart in real time.

Yes, digital twin technology can be applied to various types of machinery, equipment, infrastructure, and even complex systems. It can be adapted to a wide range of industries such as manufacturing, energy, healthcare, transportation, and more.

Our solution is designed to be compatible with various VR hardware options, including popular VR headsets available on the market. We can help you determine the best hardware solution based on your requirements and budget. Additionally, we provide affordable alternatives for organizations seeking cost-effective VR implementation.

Having a 3D model of your machinery is beneficial for creating a visual representation in the digital twin, and is needed for our solution. If there is no 3D model available, we are specialized in creating models for digital twins.

The accuracy of the digital twin representation depends on the quality and performance capabilities of the used platform. The digital twin can provide a accurate and dynamic reflection of the physical asset's behavior, performance, and conditions tailored to the targeted platform.

Yes, our digital twin solution offer customization options for the user interface and navigation controls. This allows businesses to adapt the interface to their specific needs, preferences, and branding, providing a familiar and intuitive experience for users.

A digital twin can be utilized for immersive and interactive employee training and education. It enables realistic simulations, virtual walkthroughs, and interactive tutorials, helping employees learn and practice operating procedures, maintenance tasks, and troubleshooting techniques in a safe and controlled environment.

Yes, integrating real-time data from sensors, IoT devices, or other sources is a feature of digital twin solutions. This allows the digital twin to continuously update and reflect the current state and performance of the physical asset, providing real-time insights and analytics for monitoring and decision-making.

Digital twin solutions are designed to be platform-independent and compatible with a range of devices and platforms. This includes desktop computers, mobile devices, virtual reality (VR) headsets, and other relevant technologies, ensuring flexibility and accessibility for users.

Digital twin solutions prioritize data security and employ robust measures to protect sensitive information. This includes encryption, access controls, authentication mechanisms, and compliance with data privacy regulations. Data is stored and transmitted securely to maintain the confidentiality and integrity of the digital twin and its associated information.

Yes, one of the significant advantages of a digital twin is the ability to simulate various scenarios and test changes virtually. This enables businesses to assess the impact of modifications, optimizations, or new strategies before implementing them in the physical environment, reducing risks and costs associated with real-world experimentation.

Digital twin data can provide valuable insights and analytics for performance monitoring, predictive maintenance, operational optimization, and decision-making. By analyzing the data collected from the digital twin, businesses can identify patterns, trends, anomalies, and correlations to make informed decisions, optimize processes, and enhance overall efficiency.

changes?

Digital twin solutions are designed to be flexible and adaptable to changes in the physical asset. Updating or modifying the digital twin can be relatively straightforward, depending on the complexity of the changes. By incorporating new data, adjusting parameters, or integrating additional 3d models, the digital twin can reflect the evolving state of the machinery accurately.

The level of technical expertise required depends on the specific digital twin solution and its implementation. While some solutions may require specialized knowledge, many digital twin platforms aim to provide user-friendly interfaces and intuitive tools. Training and support can be provided to ensure successful implementation and usage, even for users with varying technical backgrounds.

Yes, digital twin solutions often support collaboration and interaction among multiple users. This allows teams or stakeholders to work together within the digital twin environment, share insights, communicate, and collaborate on tasks, such as troubleshooting, maintenance planning, or design improvements. This fosters collaboration, knowledge sharing, and more efficient decision-making processes.

Digital twin solution providers typically offer various levels of support and training. This may include initial setup assistance, onboarding sessions, user documentation, and ongoing technical support. Training programs and resources may also be available to help users understand the functionalities, best practices, and potential applications of the digital twin solution.

The cost structure for implementing and maintaining a digital twin solution can vary based on factors such as the complexity of the digital twin, the size of the assets, the level of customization, and the specific requirements of the business. Typically, costs include software licensing, implementation and integration services, ongoing maintenance, and support. Providers can offer different pricing models, such as one-time fees, subscription-based models, or pay-as-you-go options.

Yes

Contact us

Testimonials

As the owner of Berg Animation GmbH, I often work with specialists on joint projects. The cooperation with Merkas Technologies was uncomplicated, reliable, of high quality and successful. Nikola and his team supported us very well in the technological implementation.

We worked with Nikola Merkas in the area of VR - parallel to the construction of the W&W Campus, our new company location, the campus was created as a VR model. This was used in various forms for internal communication and made a major contribution to the change process. The collaboration with the team around Mr. Merkas was constructive and pleasant, the quality of the work convinced us - and so did the result.